Understanding Electronic Modules Before Your Junkyard Visit

Electronic modules have become the brain centers of modern vehicles, controlling everything from transmission shifting to body functions. When searching for replacement parts at junkyards near you, testing these complex units before purchase can save hundreds of dollars and prevent frustrating installation failures.

Modern automotive electronic modules like the Body Control Module (BCM) or Transmission Control Module (TCM) are highly integrated systems that require careful evaluation. While salvage yards offer significant savings compared to dealership prices, these modules are often removed from vehicles without the ability to perform comprehensive diagnostic checks.

The Reality of Field Testing Electronic Modules

Field testing electronic modules in a salvage yard setting has inherent limitations that buyers must understand. These sophisticated control units manage numerous vehicle functions through complex network communication systems, including CAN (Controller Area Network) and LIN (Local Interconnect Network) buses.

A complete functional test requires simulating the vehicle’s entire communication network and specific load outputs – something impossible to achieve with portable equipment. However, basic field tests can confirm whether a module is completely inoperative, potentially saving you from purchasing a completely dead unit.

Essential Tools for Electronic Module Testing

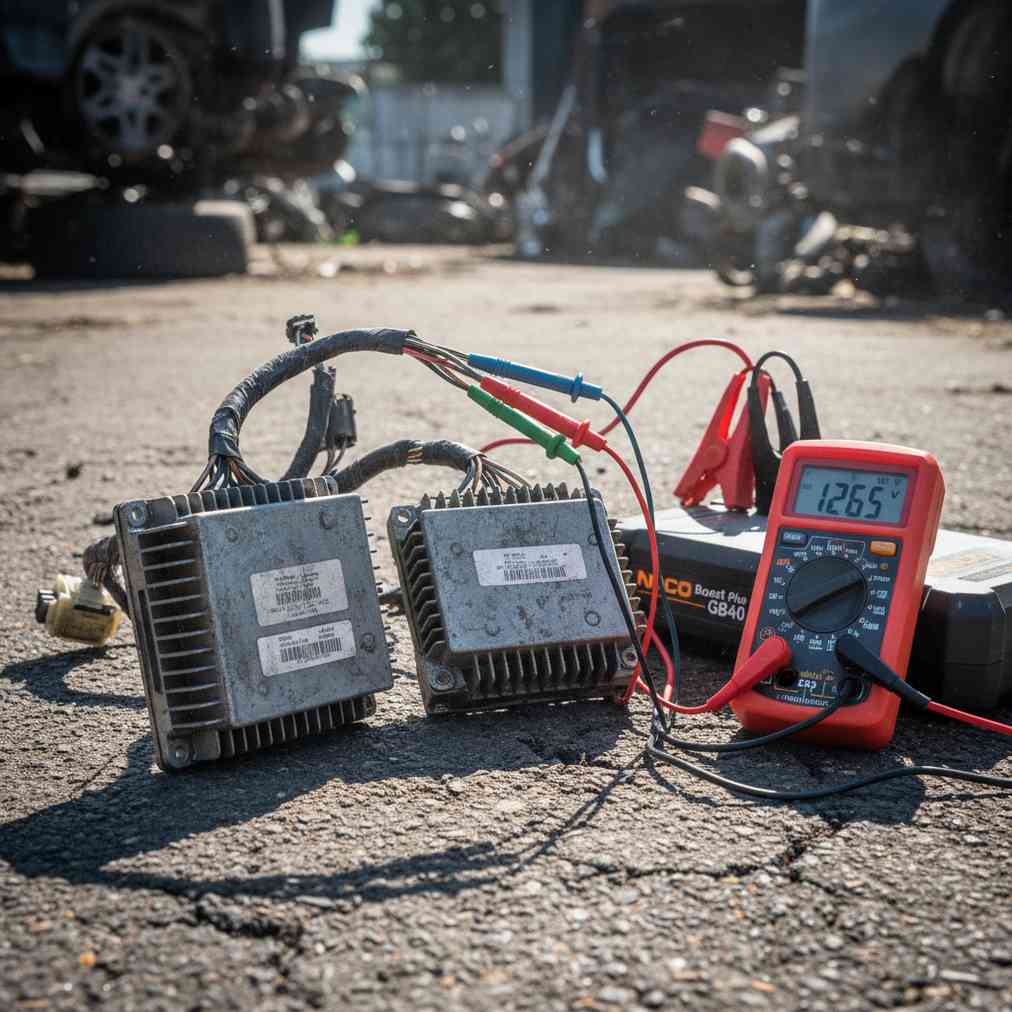

Success in field testing requires the right equipment. Since most vehicles in salvage yards have depleted batteries, you’ll need to bring your own power source and testing equipment.

- Portable 12V Power Source: A fully charged cordless drill battery (18V or 20V DeWalt/Makita) or dedicated jump starter box

- Digital Multimeter: Capable of reading DC voltage, resistance (Ω), and continuity with audible alerts

- Test Leads and Jumpers: Alligator clips for power connections and thin probes for connector pins

- Color-coded Leads: Red for positive/B+, black for negative/ground to prevent reverse polarity damage

- Flashlight: For detailed visual inspection of connector pins and module housing

Step-by-Step Field Testing Procedure

This systematic approach focuses on verifying basic power reception and checking for gross internal failures. Remember, this is a basic vitality check, not a comprehensive functional test.

| Step | Procedure | Tool Required | Expected Good Result |

|---|---|---|---|

| 1. Visual Inspection | Check for cracks, burn marks, water damage, corroded pins | Flashlight | No visible damage |

| 2. Identify Power Pins | Locate main +12V Power (B+) and Ground (GND) pins | Wiring diagram | Pins clearly identified |

| 3. Resistance Test | Check for shorts between power and ground pins | Multimeter (Ω setting) | High resistance/OL reading |

| 4. Power Application | Connect 12V source and verify voltage reception | Power pack + Multimeter | ~12V reading on power pins |

| 5. Basic Output Test | Test simple outputs if applicable (use extreme caution) | Jumper wires | Relay clicks or motor response |

Critical Safety Considerations

Electronic module testing involves working with sensitive circuits that can be permanently damaged by improper handling. Always observe these safety protocols:

- Reverse Polarity Protection: Double-check positive and negative connections before applying power

- Avoid Pin Damage: Use appropriate probe sizes to prevent connector pin damage or short circuits

- Voltage Verification: Ensure your power source provides stable 12V output, not significantly higher

- Static Discharge: Ground yourself before handling sensitive electronic modules

Visual Inspection: Your First Line of Defense

Before connecting any power, conduct a thorough visual examination. This step alone can save you from purchasing obviously damaged units.

Inspect the module housing for cracks, burn marks, or signs of water intrusion. Pay special attention to connector pins – look for corrosion, bending, or complete breakage. Green corrosion on pins indicates water damage, while burnt or melted areas suggest electrical failures.

Check for obvious physical damage like impact marks or missing components. If you find any of these issues, move on to another unit regardless of the price – these problems typically indicate internal damage that field testing cannot detect.

Understanding Power Pin Identification

Identifying the correct power pins is crucial for safe testing. Most automotive electronic modules require constant 12V power (B+) and a solid ground connection (GND). Some modules also have switched power inputs that activate specific functions.

Without access to factory service manuals, pin identification can be challenging. Look for thicker wires in the harness – these often indicate power and ground connections. Some connectors have pin numbering that can help with identification using online resources.

When in doubt, start with the most obvious candidates and work systematically. Never guess blindly, as incorrect connections can damage both the module and your testing equipment.

Interpreting Test Results

Understanding what your test results mean is crucial for making informed purchasing decisions. Here’s how to interpret common findings:

Resistance Testing Results: A reading near 0Ω between power and ground indicates a short circuit – avoid this module. High resistance or “OL” (open loop) readings suggest the internal circuits are intact.

Power Application Results: If the module accepts 12V without immediately drawing excessive current (indicated by your power source shutting down), this suggests basic circuit integrity. However, this doesn’t guarantee functional operation.

Output Testing Results: Simple outputs like relay clicks or motor responses provide basic confirmation of internal activity, but remember that complex modules may not show obvious external signs of operation without proper system integration.

Limitations and Realistic Expectations

Field testing with portable equipment has significant limitations that buyers must understand. These tests can identify completely dead modules but cannot verify:

- Network Communication: CAN/LIN bus functionality requires specialized equipment

- Programming Integrity: Software corruption is invisible to basic electrical tests

- Intermittent Failures: Problems that occur under specific conditions

- Security Functions: VIN matching and anti-theft features

Modern automotive electronics trend toward greater integration and security features, making field testing less definitive than with older, simpler components. Recent developments in automotive electronics and AI integration have increased module complexity significantly.

Common Module Types and Testing Approaches

Different types of electronic modules require tailored testing approaches based on their complexity and function.

Body Control Modules (BCM): These units manage lighting, door locks, and accessory functions. Look for basic power acceptance and check if any relays click when power is applied. Some BCMs have LED indicators that may illuminate during power-up.

Transmission Control Modules (TCM): These are among the most complex modules to test in the field. Basic power acceptance testing is about all you can accomplish without vehicle integration. Look for signs of heat damage, as TCMs often fail due to thermal stress.

Engine Control Modules (ECM/PCM): Similar to TCMs in complexity, these units require extensive system integration for proper testing. Focus on visual inspection and basic power acceptance.

Advanced Testing Considerations

For those with more technical expertise, additional testing methods can provide deeper insights into module condition.

Current draw testing can reveal internal short circuits or excessive power consumption. A normal module should draw minimal current when powered but not actively communicating. Excessive current draw (typically over 100mA for most modules) suggests internal damage.

Some experienced technicians use oscilloscopes to check for basic microprocessor activity by monitoring power supply ripple or looking for clock signals on data pins. However, this requires significant expertise and specialized equipment.

Documentation and Record Keeping

Keep detailed records of your testing process and results. Document the module’s part number, the vehicle it came from, and your test results. This information proves invaluable if issues arise after installation.

Take photos of connector pins and any identifying labels before and after testing. These images can help with troubleshooting installation issues or provide evidence if you need to return a defective part.

Modern techniques for data analysis and documentation can help you track patterns in module failures and success rates, improving your future purchasing decisions.

Cost-Benefit Analysis of Field Testing

While field testing requires additional time and equipment, the potential savings justify the effort. New electronic modules can cost thousands of dollars, while salvage yard units typically sell for 10-30% of new prices.

Even basic testing can eliminate obviously defective units, significantly improving your success rate. Consider that a failed module installation often requires removal and reinstallation costs, making the initial testing investment worthwhile.

When evaluating whether to sell your junk car for cash or use it as a parts donor, remember that electronic modules often retain significant value even in non-running vehicles.

Alternative Testing Strategies

If field testing seems too complex or risky, consider these alternative approaches:

- Purchase from reputable salvage yards that offer limited warranties on electronic parts

- Buy multiple units if the price is low enough to account for potential failures

- Focus on visual inspection and purchase only pristine-appearing modules

- Seek modules from low-mileage donor vehicles with known service histories

Future Trends in Module Testing

The automotive industry continues evolving toward greater electronic integration. Machine learning and AI applications in vehicle systems make modules increasingly complex and difficult to test in isolation.

Future developments may include portable diagnostic tools specifically designed for salvage yard testing, but current technology limitations mean basic electrical testing remains the primary field option.

“The trend in automotive electronics is toward greater integration and security, which makes field testing less effective for complex modules compared to older, simpler components. This reinforces the need for visual inspection and basic power checks as the primary diagnostic tools available to salvage yard customers.”

Making the Final Purchase Decision

After completing your field testing, weigh all factors before purchasing. A module that passes basic tests isn’t guaranteed to work, but one that fails basic tests is almost certainly defective.

Consider the total cost including potential programming requirements, as many modern modules require dealer or specialist programming to function properly in your vehicle. Factor this additional cost into your decision-making process.

Remember that electronic module testing in salvage yards represents a calculated risk. While basic field testing can improve your odds of success, it cannot guarantee functionality. Approach each purchase with realistic expectations and appropriate contingency planning.

The combination of thorough visual inspection, basic electrical testing, and careful documentation provides the best available method for evaluating electronic modules in salvage yard environments. While not foolproof, this approach significantly improves your chances of finding functional replacement parts at substantial savings compared to new components.

Leave a Reply

You must be logged in to post a comment.