When your car’s turbocharger fails, you’ll notice loss of power, smoke from the exhaust, or strange whining sounds. Replacing it with a new unit can easily cost $1,500–$3,000, but junkyards and salvage yards often have OEM turbochargers for a fraction of the price. While buying used can offer significant savings, it comes with inherent risks and requires careful inspection. This comprehensive guide will help you navigate the process, perform critical checks, and make an informed decision to increase your chances of success.

In this guide, we’ll cover:

- What a turbocharger is and why cars use them

- How much a used turbocharger costs at junkyards

- Critical inspection checklist before buying

- Tools and tips for removing one yourself

- Essential installation steps for maximum longevity

- Durability expectations and rebuild considerations

- Warning signs to avoid problematic turbos

- Comprehensive FAQ section

What is a Turbocharger?

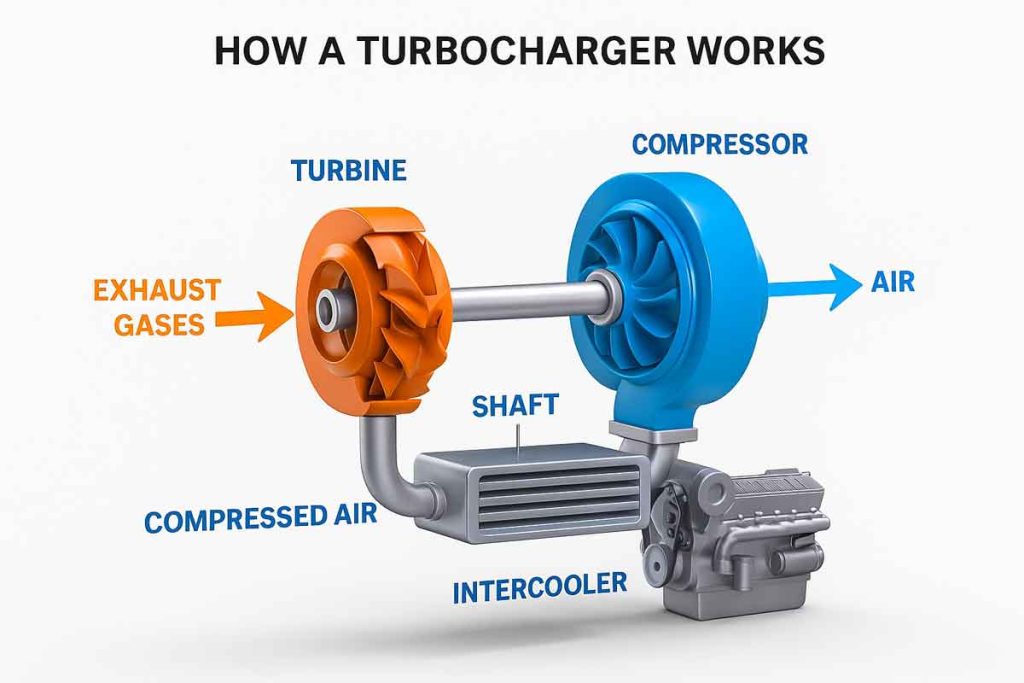

A turbocharger is an exhaust-driven forced induction device that significantly enhances engine performance by compressing incoming air before it enters the combustion chamber. This allows the engine to burn more fuel efficiently, producing substantially more power without increasing engine displacement.

Key Components:

- Compressor wheel – compresses incoming air before it enters the engine

- Turbine wheel – spun by hot exhaust gases exiting the engine

- Center housing rotating assembly (CHRA) – contains the shaft and bearings connecting turbine and compressor

- Wastegate/actuator – regulates boost pressure by directing excess exhaust gas around the turbine

- Oil feed and drain lines – provide critical lubrication to high-speed bearings

Turbochargers operate at extremely high speeds (often exceeding 150,000 RPM) and temperatures up to 1,800°F, making proper lubrication absolutely critical.

In simple terms: A turbo lets a smaller, more fuel-efficient engine perform like a larger, more powerful one, offering better performance and often improved fuel economy when properly matched to the engine.

How Much Does a Used Turbocharger Cost at a Junkyard?

Prices for used turbochargers vary significantly based on vehicle make, model, turbo rarity, condition, and salvage yard location. Here’s what you can expect to pay:

| Vehicle Type | Junkyard Turbo Price | New Turbo Price | Potential Savings |

|---|---|---|---|

| Compact cars (VW Golf, Ford Focus) | $100 – $250 | $900 – $1,500 | 75–85% |

| Mid-size sedans (BMW 3-Series, Audi A4) | $250 – $600 | $1,800 – $3,000 | 70–80% |

| Luxury/Performance (BMW M-Series, Audi S-Line) | $400 – $1,000 | $2,500 – $4,500 | 60–75% |

| Diesel trucks (Ford Powerstroke, Cummins) | $400 – $800 | $2,500 – $4,000 | 70–85% |

| Rare/High-performance applications | $600 – $1,500 | $3,000 – $6,000+ | 50–75% |

💡 Pro tip: If visiting a self-service junkyard, bring your own tools and review junkyard safety guidelines beforehand. Call ahead to check inventory—many yards now have computerized systems showing available vehicles.

Critical Inspection Checklist: What to Check Before Buying

Thorough inspection is your best defense against purchasing a failed or failing turbocharger. Here’s your detailed inspection checklist:

1. Shaft Play Assessment (Most Critical)

Axial Play (In-and-out movement): There should be virtually no movement when pushing and pulling the compressor wheel. Excessive axial play indicates worn thrust bearings—a costly repair.

Radial Play (Side-to-side movement): A small amount is normal due to necessary clearances, but the shaft shouldn’t touch the compressor housing walls when moved. If you hear scraping or feel resistance, walk away.

How to test: Gently grip the compressor wheel (not the blades) and check movement in all directions.

2. Compressor and Turbine Wheel Inspection

Look for:

– Blade damage: Nicks, chips, bends, cracks, or missing pieces

– Foreign object damage (FOD): Evidence of debris ingestion

– Blade tip wear: Shiny marks indicating contact with housing

– Wheel balance: Bent or damaged wheels will cause vibration and rapid bearing failure

Red flags: Any visible damage to wheel blades typically means the turbo has ingested debris and may have internal damage.

3. Housing Condition Assessment

Check for cracks: Look carefully at the turbine housing, especially around wastegate ports where heat cycling causes stress cracking.

Inspect for:

– Warping from overheating

– Thread damage on mounting surfaces

– Corrosion that could indicate coolant leaks

– Heat damage (extreme discoloration)

4. Oil System Inspection

Oil leaks: Check both compressor and turbine sides for oil residue, which can indicate seal failure. A small amount of oil residue is sometimes normal, but heavy oil coating is concerning.

Check:

– Oil feed port for blockages or carbon buildup

– Oil drain port condition

– Internal oil passages (use a flashlight)

– Evidence of oil starvation (scoring or discoloration)

5. Wastegate Operation

Mechanical wastegate: Should move freely without binding or excessive play

Electronic actuator: Look for damaged wiring or corroded connections

Vacuum lines: Check for cracks or disconnection

6. Mounting Points and Connections

- Exhaust flange: Should be flat without warping

- Oil and coolant fittings: Check for damage or cross-threading

- Mounting studs: Look for damage or corrosion

Warning Signs: When to Walk Away

Immediately avoid turbos with:

❌ Significant shaft play (especially axial movement)

❌ Damaged compressor or turbine wheels (any blade damage)

❌ Cracked or warped housings

❌ Evidence of oil starvation (scoring, discoloration)

❌ Seized wastegate actuator

❌ Heavy oil contamination throughout

❌ Unknown history from high-mileage or abused vehicles

Remember: Rebuilding a damaged turbo can cost $300-$800+ in parts and labor, potentially negating your savings.

Essential Tools for Self-Service Removal

Removing a turbocharger requires specific tools beyond basic auto parts retrieval:

Must-have tools:

– Socket set with deep sockets and extensions

– Metric and SAE wrenches (most turbos use metric)

– Penetrating oil (PB Blaster, Liquid Wrench)

– Breaker bar (turbo bolts are often very tight)

– Heavy-duty gloves and safety glasses

– Small mirror and flashlight (for inspection)

Vehicle-specific tools you might need:

– Torx bit set (European vehicles)

– Line wrenches (for oil fittings)

– Heat gun (for stuck bolts)

– Anti-seize compound (for reassembly)

⚠️ Safety tip: Turbochargers can be heavy (15–25 lbs) and have sharp edges. Use proper lifting techniques and protective equipment.

Professional Installation Guide for Maximum Longevity

Proper installation is critical for any turbocharger’s longevity, but especially important with used units of unknown history.

Pre-Installation (Critical Steps)

1. Engine Preparation:

– Change engine oil and filter with high-quality synthetic oil

– Flush oil system if contamination is suspected

– Check oil pressure to ensure adequate lubrication

2. Oil System Service:

– Replace oil feed line (highly recommended—internal coking is hard to detect)

– Clean oil return line thoroughly

– Inspect oil pickup screen for debris

– Verify proper oil pressure (minimum 10 psi at idle, 40+ psi at 2000 RPM)

3. Air System Cleaning:

– Clean/replace intercooler (failed turbos contaminate the system)

– Inspect all intake piping for oil residue

– Replace air filter

– Check for boost leaks

4. Turbo Preparation:

– Prime with clean oil before installation

– Spin shaft by hand to distribute oil

– Inspect all gaskets and seals

Installation Best Practices

Critical steps:

– Use new gaskets for all connections

– Apply proper torque specifications (over-tightening can warp housings)

– Use anti-seize on exhaust connections

– Route oil lines properly to prevent kinking

Post-Installation Protocol

Startup procedure:

1. Prime oil system: Crank engine without ignition for 15–20 seconds

2. Check for leaks before starting

3. Initial start: Let engine idle for 5 minutes minimum

4. Gradual warm-up: Avoid boost until fully warmed

5. Break-in period: Gentle driving for first 500 miles

Durability and Lifespan Expectations

New turbocharger lifespan: 150,000–200,000+ miles with proper maintenance

Used turbocharger variables:

– Unknown maintenance history

– Previous operating conditions

– Installation quality

– Ongoing maintenance

With careful selection and proper installation, a quality used turbo can provide 50,000–100,000+ miles of service, but this varies greatly depending on the factors above.

Factors affecting longevity:

– Oil change frequency (most critical factor)

– Proper warm-up and cool-down procedures

– Air filter maintenance

– Quality of gasoline/diesel fuel

– Driving habits (aggressive vs. conservative)

Understanding Rebuild Options

If you find a turbo with good housings but questionable internals, rebuilding might be an option:

Rebuild kit costs: $75-$300+ (depending on turbo type)

Professional rebuild: $400-$800+

DIY rebuild challenges:

– Requires specialized balancing equipment

– Clean room environment preferred

– Precision assembly critical

– Special tools needed

When rebuilding makes sense:

– Rare or expensive turbocharger

– Good housing condition

– You have mechanical experience

– Access to proper tools

Turbocharger Matching and Compatibility

Critical matching factors:

– Compressor sizing (match airflow requirements)

– Turbine housing A/R ratio (affects spool characteristics)

– Oil fitting sizes and locations

– Physical clearance in engine bay

– Wastegate type (internal vs. external)

❗ Important: Using a turbocharger not designed for your engine requires careful consideration of fueling, ignition timing, and boost control systems.

Pros and Cons Summary

| Pros | Cons |

|---|---|

| ✅ Significant cost savings (50–85%) | ❌ Unknown history and potential hidden damage |

| ✅ OEM fit and performance characteristics | ❌ May require immediate rebuilding |

| ✅ Good option for older or discontinued models | ❌ Higher risk of premature failure |

| ✅ Environmental benefits (recycling) | ❌ Installation requires careful attention |

| ✅ Availability for project cars | ❌ Limited or no warranty coverage |

| ✅ Learning opportunity for DIY mechanics | ❌ Potential for associated system damage |

Related Resources

Essential reading:

– Used Auto Parts Price Guide

– Self-Service Auto Parts: How It Works

– Junkyard Safety Tips

– What Car Parts Are Worth the Most?

– Finding Quality Used Auto Parts

Frequently Asked Questions

Q: Is it safe to buy a used turbo from a junkyard?

A: It can be safe with thorough inspection and proper installation. The key is knowing what to look for and understanding the risks. Never skip the inspection checklist, and be prepared for the possibility of needing a rebuild.

Q: How much should I expect to pay for a used turbo?

A: Prices typically range from $100 to $1,500, depending on vehicle type, turbo rarity, and condition. Common applications (VW, Ford, etc.) are usually on the lower end, while rare or high-performance turbos cost more.

Q: Can I rebuild a junkyard turbo myself?

A: While rebuild kits are available ($75-$300+), turbo rebuilding requires precision tools, clean working conditions, and mechanical expertise. Most importantly, the rotating assembly must be professionally balanced. DIY rebuilding is possible but challenging.

Q: Will a junkyard turbo improve my car’s fuel economy?

A: If properly sized and in good condition, a turbo can help restore optimal performance and potentially improve fuel economy. However, a failing or incorrectly sized turbo will negatively impact efficiency.

Q: What’s the difference between OEM and aftermarket turbos at junkyards?

A: Junkyards primarily stock OEM (Original Equipment Manufacturer) turbos from salvaged vehicles. Aftermarket performance turbos are less common unless they were originally installed on enthusiast-owned vehicles.

Q: How can I tell if a used turbo will fit my car?

A: Check the part number against your vehicle’s specifications, verify mounting points, and ensure oil fitting compatibility. When in doubt, bring your old turbo for comparison or consult a professional.

Q: What should I do if the used turbo fails shortly after installation?

A: First, determine the cause of failure to prevent damaging a replacement. Common causes include oil starvation, contamination, or improper installation. Address root causes before installing another turbo.

Q: Are remanufactured turbos better than used ones?

A: Remanufactured turbos undergo professional inspection, cleaning, and rebuilding with new components. While more expensive than used turbos, they offer greater reliability and often come with warranties.

Q: How long should I expect a used turbo to last?

A: Lifespan varies greatly depending on condition, installation quality, and maintenance. A well-selected used turbo with proper installation and maintenance could last 50,000–100,000+ miles, but there are no guarantees.

Q: What are the most reliable turbo brands to look for in junkyards?

A: Look for OEM turbos from reputable manufacturers like Garrett, BorgWarner, IHI, and Mitsubishi Heavy Industries. These companies supply turbos to major automakers and generally build quality units.

Q: Should I buy a used turbo online or from a local junkyard?

A: Local junkyards allow hands-on inspection, which is crucial for turbos. Online purchases should include detailed photos and return policies. If buying online, only purchase from reputable sellers with good return policies.

Q: What maintenance should I do after installing a used turbo?

A: Change oil frequently (every 3,000–5,000 miles), use high-quality synthetic oil, replace air filters regularly, allow proper warm-up and cool-down time, and monitor for oil leaks or unusual sounds.

This guide represents general information for educational purposes. Always consult qualified mechanics for your specific situation and follow all safety procedures when working on vehicles.

Leave a Reply

You must be logged in to post a comment.