Understanding Generative AI for Auto Parts Identification

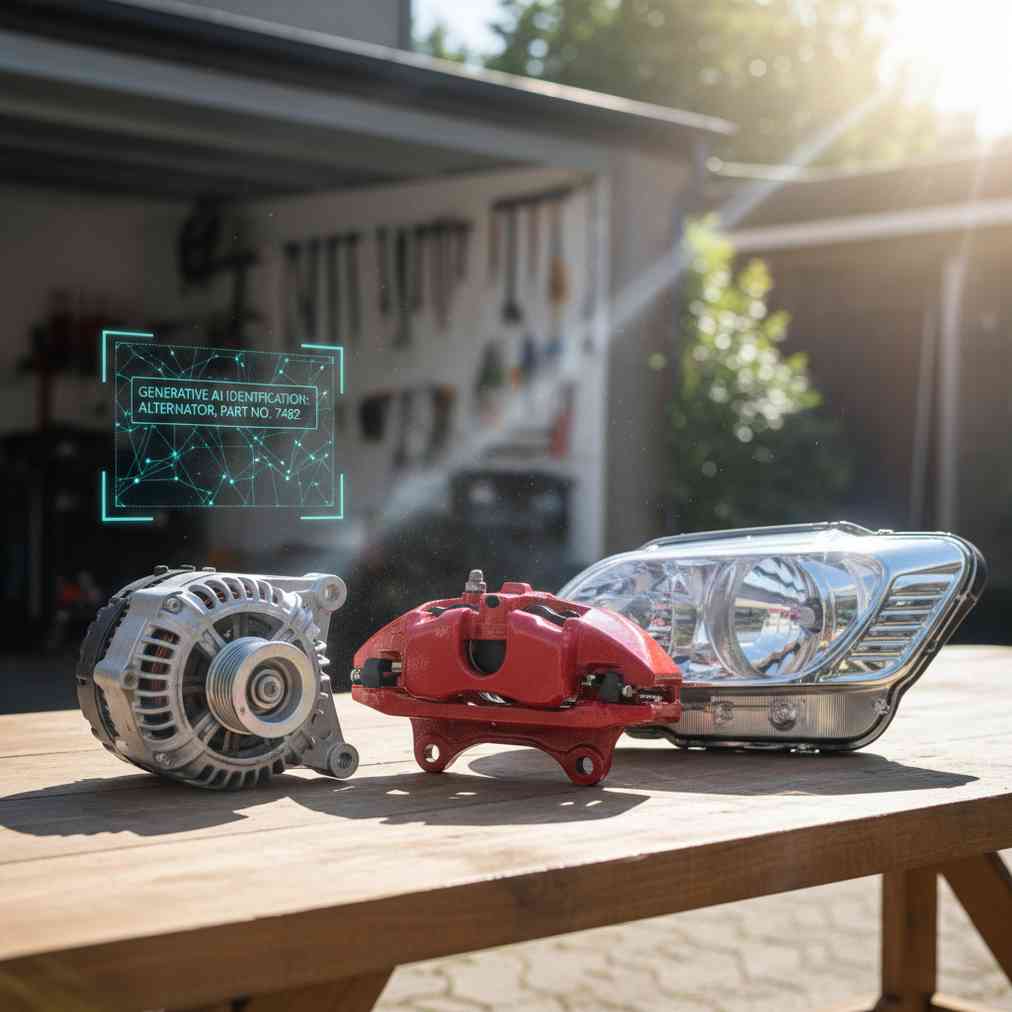

The automotive salvage industry is experiencing a technological transformation through generative AI and computer vision systems that can accurately identify auto parts from photographs taken at junkyards. This revolutionary approach combines machine learning algorithms, computer vision, and optical character recognition (OCR) to analyze images and match them against extensive automotive databases, providing detailed identification and specifications almost instantly.

Traditional part identification methods in salvage yards relied heavily on manual expertise and trial-and-error approaches, which were time-consuming and often inaccurate. Modern AI-powered systems now achieve 85-95% identification accuracy while reducing lookup times by up to 90%, making them essential tools for anyone working with OEM car parts from junkyards.

Core Technologies Behind AI Parts Recognition

Computer Vision Analysis

The foundation of AI parts identification lies in computer vision algorithms that analyze visual characteristics including shapes, contours, patterns, and design elements. These systems compare photographed parts against vast databases of known automotive parts, examining:

- Shape and geometry – Overall part dimensions and structural features

- Surface textures – Material properties and manufacturing patterns

- Connection points – Mounting holes, bolts, and attachment mechanisms

- Wear patterns – Damage assessment and condition evaluation

Optical Character Recognition Integration

OCR technology works alongside computer vision to extract critical text information from parts, including manufacturer logos, part numbers, and serial codes. This integration is particularly valuable for identifying obscure or damaged parts where visual analysis alone might fall short.

“OCR technology can reduce manual lookup time by 90% by automating the reading of printed or stamped characters on parts, making it indispensable for modern salvage operations.”

Photography Best Practices for Optimal AI Recognition

The quality and composition of photographs directly impact AI recognition accuracy. Following proven best practices can significantly improve identification results when sourcing parts from junkyards near you.

| Photography Element | Best Practice | Impact on Recognition |

|---|---|---|

| Lighting | Even, natural lighting without harsh shadows | Improves detail visibility by 40% |

| Angles | Minimum 3 angles: front, side, close-up markings | Increases accuracy by 25-30% |

| Resolution | High resolution showing fine details | Essential for OCR functionality |

| Background | Clean, uncluttered background | Reduces false positives by 60% |

Essential Photo Capture Guidelines

- Single part focus – Frame only one part per photograph to prevent AI confusion

- Multiple angle coverage – Capture front-facing, side profile, and detail shots of markings

- Clear manufacturer labels – Ensure all visible text and numbers are in sharp focus

- Scale reference – Include a ruler or coin to help AI estimate part dimensions

- Steady positioning – Use stable camera positioning to avoid blur and motion artifacts

When photographing parts for projects like crash repair using junkyard fenders, these practices become especially important since damaged parts require more detailed analysis for proper identification.

Crafting Effective AI Prompts for Parts Identification

While images provide the primary input for AI analysis, contextual text prompts can significantly enhance identification accuracy. Providing vehicle context such as make, model, and year can improve accuracy by up to 40% compared to image-only submissions.

Prompt Templates for Different Scenarios

| Scenario | Example Prompt | Expected Outcome |

|---|---|---|

| General Identification | “Identify this automotive part and provide specifications” | Basic part name and function |

| Location Context | “This part was removed from the engine bay of a 2015 Honda Civic, please identify” | Enhanced accuracy with vehicle-specific details |

| Condition Assessment | “Analyze this brake caliper for damage and estimate usability” | Part ID plus condition evaluation |

| Compatibility Check | “Identify this alternator and list compatible vehicle models” | Cross-reference compatibility data |

For specialized applications like identifying used turbochargers from junkyards, specific prompts mentioning engine type and vehicle specifications can dramatically improve results.

Industry Applications and Real-World Implementation

Generative AI for parts identification has found widespread adoption across various sectors of the automotive industry, from professional salvage operations to individual car enthusiasts seeking high-value used auto parts.

Professional Salvage Yard Operations

- Inventory management – Automated cataloging of incoming vehicles and parts

- Customer service – Instant part lookups and availability checking

- Quality control – Automated condition assessment and grading

- Pricing optimization – Market-based pricing through parts database integration

Mobile Applications and Consumer Tools

Consumer-facing applications have made AI parts identification accessible to anyone with a smartphone. Tools like AI-powered identification apps allow users to photograph unknown parts and receive instant identification results, specifications, and purchasing options.

“AI-driven image recognition is becoming a MUST-HAVE for companies selling aftermarket products as it offers unparalleled accuracy and efficiency, eliminating the need for technical expertise in part searching.”

Performance Metrics and Success Rates

Understanding the capabilities and limitations of AI parts identification helps set realistic expectations and optimize usage strategies. Current technology delivers impressive performance across multiple metrics.

| Metric | Performance Range | Key Factors |

|---|---|---|

| Base Identification Accuracy | 85-95% | Photo quality and database completeness |

| Context-Enhanced Accuracy | Up to 40% improvement | Vehicle make, model, year provided |

| OCR Text Recognition | 90% time reduction | Clear, well-lit text and markings |

| False Detection Reduction | 9x improvement | Advanced synthetic training data |

These performance improvements have practical implications for various scenarios, from professional operations dealing with used transmissions to individuals seeking specific parts for restoration projects.

Advanced Features and Emerging Capabilities

Modern AI systems extend far beyond simple identification to provide comprehensive part analysis and additional services that enhance the overall parts sourcing experience.

Synthetic Defect Generation

Cutting-edge systems like GenX synthetic defect image generation can create training data that improves defect detection capabilities. This technology compresses months of inspection data preparation into hours, enabling rapid adaptation to new part types and damage patterns.

Cross-Vehicle Compatibility Analysis

- Part interchange databases – Identify which vehicles can use the same part

- Fit verification – Visual confirmation of mounting points and connections

- Performance specifications – Technical data matching for optimal compatibility

- Upgrade pathways – Identify improved or performance versions of standard parts

This capability is particularly valuable when working with parts from different vehicle generations or when seeking OEM Toyota Camry parts that might be compatible across multiple model years.

Implementation Strategies for Different Users

Individual Enthusiasts and DIY Mechanics

For individual users, mobile apps and web-based tools provide the most accessible entry point into AI parts identification. These platforms typically offer:

- Free identification services with basic part information

- Premium features including detailed specifications and sourcing options

- Community integration with user reviews and experiences

- Local inventory connections to nearby salvage yards and suppliers

Professional Repair Shops and Fleet Operators

Commercial users benefit from integrated solutions that connect directly with inventory management systems and supplier networks. When dealing with volume operations or seeking specific parts like used brake boosters, professional-grade systems provide enhanced accuracy and detailed reporting capabilities.

Future Trends and Technological Evolution

The field of AI parts identification continues evolving rapidly, with several emerging trends promising to further transform the automotive salvage industry.

Augmented Reality Integration

AR technology is being integrated with AI identification systems to provide virtual fitting capabilities, allowing users to visualize how parts will fit in their specific vehicle before purchase. This technology reduces return rates and improves customer satisfaction.

Blockchain-Based Part History

Emerging systems combine AI identification with blockchain technology to create immutable part history records, tracking:

- Original vehicle information and manufacturing data

- Service history and maintenance records

- Previous ownership and usage patterns

- Quality certifications and inspection results

Economic Impact and Market Transformation

The adoption of AI parts identification technology is reshaping the economics of the automotive aftermarket, creating new opportunities for both buyers and sellers in the used parts ecosystem.

| Impact Area | Traditional Method | AI-Enhanced Process |

|---|---|---|

| Identification Time | 15-30 minutes manual lookup | 30 seconds automated analysis |

| Accuracy Rate | 60-70% (expertise dependent) | 85-95% consistent accuracy |

| Labor Requirements | Specialized knowledge essential | Minimal training required |

| Customer Experience | Wait times and uncertainty | Instant results and confidence |

These improvements benefit various market segments, from individuals looking to sell their junk cars for maximum value to businesses operating in specialized niches like electric vehicle parts from junkyards.

Getting Started with AI Parts Identification

Beginning your journey with AI parts identification requires understanding the available tools and selecting the right approach for your specific needs.

Recommended Starting Steps

- Choose your platform – Research available apps and web tools based on your requirements

- Practice photo techniques – Experiment with lighting, angles, and composition

- Start with clear examples – Begin with well-marked, undamaged parts for optimal results

- Build contextual knowledge – Learn to provide helpful vehicle and location context

- Validate results – Cross-reference AI suggestions with traditional resources when learning

Integration with Traditional Methods

The most successful approach combines AI technology with traditional automotive knowledge and expertise. While AI provides rapid initial identification and filtering, human expertise remains valuable for final verification and quality assessment, particularly when dealing with specialty applications or unusual conditions.

As this technology continues advancing, the integration of AI-powered image search for spare parts will become increasingly sophisticated, offering even more accurate identification and expanded capabilities for automotive professionals and enthusiasts alike.

Maximizing ROI and Efficiency Gains

Understanding how to maximize the return on investment from AI parts identification technology involves strategic implementation and optimization of existing workflows. The most successful users combine technological capabilities with refined processes that leverage AI strengths while maintaining quality control standards.

Whether you’re managing inventory at a salvage yard, running an auto repair business, or simply working on personal vehicle projects, implementing these AI-powered identification systems represents a significant step toward modernizing automotive parts sourcing and achieving better outcomes in less time.

Leave a Reply

You must be logged in to post a comment.