Understanding the Source of That Annoying Rattle

When your car starts making mysterious rattling noises from the exhaust system, it’s time to investigate before the problem worsens. That telltale rattle often signals that your muffler or exhaust pipes need attention, but determining whether it’s a simple fix or requires replacement is crucial for both your wallet and your vehicle’s performance.

Diagnosing External vs Internal Rattles

The first step in diagnosing exhaust rattles involves distinguishing between external and internal issues. External rattles typically stem from loose heat shields or deteriorated muffler hangers, while internal rattles indicate more serious problems with the muffler’s internal structure.

External Rattle Sources

- Heat shields – Metal covers that protect surrounding parts from exhaust heat

- Muffler hangers – Rubberized supports prone to corrosion and wear

- Pipe hangers – Support brackets that can loosen over time

- Loose clamps – Connection points that may need tightening

The Internal Baffle Test

To check for internal muffler damage, perform this simple diagnostic test when the exhaust system is completely cold:

- Gently tap the muffler with a rubber mallet or the back of your fist

- Listen carefully for distinct rattling sounds from inside

- Test different areas of the muffler housing

- Compare sounds between suspect and known good sections

“If tapping the muffler with a mallet reveals rattling on the inside, odds are there’s quite a bit of rust that’s accumulated and eaten up the inside. That would warrant replacement of the muffler itself.”

Understanding Double-Walled Exhaust Parts

Many modern exhaust systems feature double-walled construction for better heat insulation and noise reduction. When the inner pipe breaks loose from the outer shell, it creates a distinctive rattle that requires localized inspection to pinpoint the exact location.

| Rattle Type | Typical Cause | Repair Difficulty |

|---|---|---|

| External | Loose heat shields/hangers | Easy – temporary fixes available |

| Internal Baffle | Rust accumulation/corrosion | Hard – replacement recommended |

| Double-wall separation | Inner pipe displacement | Medium – depends on accessibility |

Comprehensive Visual Inspection Checklist

Whether you’re examining your current exhaust system or evaluating a potential replacement from a salvage yard near me, a thorough visual inspection is essential for making informed decisions.

Surface Damage Assessment

- Dents and physical damage – Check for impact damage that could affect airflow

- Cracks in the housing – Look for stress fractures, especially near weld points

- Holes of any size – Even small holes cause exhaust leaks and performance issues

- Mounting bracket integrity – Ensure attachment points are solid and rust-free

The Critical Rust Evaluation

Surface rust may appear concerning but often poses minimal threat. However, deep or widespread rust compromises structural integrity and indicates potential failure points.

Perform the integrity test by gently prodding rusty areas with a screwdriver. If the metal feels weak, splits easily, or flakes away, the part should be rejected regardless of price.

Modern Exhaust Materials and Corrosion Resistance

Today’s exhaust systems often utilize 13% chrome stainless steel construction, offering superior corrosion resistance compared to traditional materials. However, even stainless steel succumbs to road salt and environmental factors over time, particularly in harsh climates.

Modern catalytic converters produce water and CO₂ as byproducts during the emission control process. This moisture can become trapped in the exhaust system, contributing to internal corrosion from the catalytic converter back through the entire system.

Identifying Connection Point Failures

Critical inspection areas include all welds and pipe connections where different sections join together. Look for these warning signs:

- Black soot deposits around joints indicating exhaust leaks

- Cracked welds that compromise structural integrity

- Corroded clamp areas where water and debris accumulate

- Loose or missing bolts at flange connections

Performance Impact of Exhaust System Damage

A damaged muffler affects more than just noise levels. Key performance indicators include:

| Symptom | Cause | Impact Level |

|---|---|---|

| Louder exhaust noise | Holes or damaged baffles | Moderate |

| Reduced fuel efficiency | Back-pressure changes | Significant |

| Loss of engine power | Restricted exhaust flow | Major |

| Cabin exhaust smell | System leaks | Critical Safety Issue |

Temporary Fixes vs Permanent Solutions

While muffler tape or epoxy can temporarily seal small holes, these solutions are stopgap measures at best. For significant damage, replacement remains the most reliable long-term solution.

External rattles from loose heat shields can often be addressed with hose clamps or steel zip ties as inexpensive temporary fixes. However, internal baffle failure requires complete muffler replacement.

Finding Quality Replacement Parts at Salvage Yards

When searching for replacement exhaust parts, salvage yards offer significant savings over new parts. Focus your inspection on these key areas:

- Matching your vehicle’s specifications – Ensure compatibility with your exact make, model, and year

- Checking internal condition – Perform the tap test on any prospective replacement

- Evaluating rust patterns – Brown surface rust may be acceptable, but multiple rust colors indicate advanced corrosion

- Testing mounting points – Verify that all attachment brackets and hangers are intact

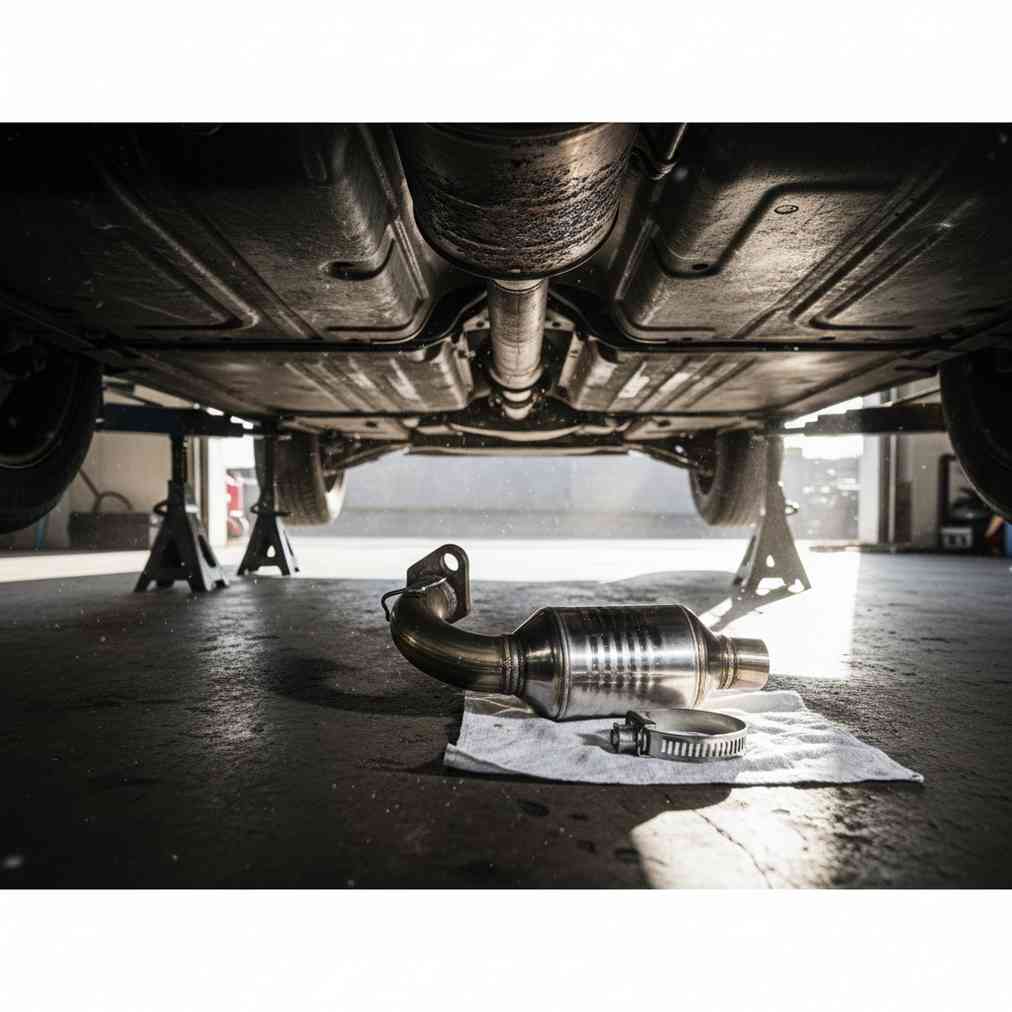

Safe Removal Techniques

When removing exhaust parts from donor vehicles, safety should be your primary concern. Essential tools include:

- Safety glasses and gloves – Protection from rust flakes and sharp edges

- Penetrating oil – For loosening corroded connections

- Proper cutting tools – When bolts cannot be removed

- Jack and stands – Never work under a vehicle supported only by a floor jack

Installation Considerations

Installing a replacement muffler involves more than simply bolting on the new part. Consider these factors:

- Gasket replacement – Always use new gaskets at connection points

- Proper alignment – Ensure the exhaust system doesn’t contact the undercarriage

- Torque specifications – Follow manufacturer guidelines for clamp tightness

- System testing – Check for leaks after installation

When to Consider Professional Help

While many exhaust repairs are within the scope of DIY mechanics, certain situations warrant professional attention:

- Catalytic converter issues – Requires specialized knowledge and equipment

- Complex routing problems – When exhaust pipes interfere with other systems

- Welding requirements – Custom fabrication or permanent repairs

- Safety concerns – If you’re uncomfortable working under the vehicle

Environmental and Economic Benefits

Choosing salvaged exhaust parts over new ones provides both environmental benefits and significant cost savings. By extending the life of existing parts through reuse, you’re contributing to reduced manufacturing demand while keeping functional parts out of landfills.

If your current vehicle has reached the end of its useful life and you’re considering cash for junk cars, remember that even damaged vehicles contain valuable parts that can benefit other car owners through the salvage system.

Making the Final Decision

The decision between repair and replacement ultimately depends on the severity of the damage and the overall condition of your exhaust system. Internal baffle failure, significant rust damage, or multiple system leaks typically justify complete replacement, while external rattles may respond well to targeted repairs.

Remember that a properly functioning exhaust system is crucial for vehicle performance, fuel efficiency, and passenger safety. When in doubt, prioritize safety and choose the repair option that provides the most reliable long-term solution for your specific situation.

By following these diagnostic steps and inspection guidelines, you’ll be well-equipped to identify exhaust problems early and make informed decisions about repairs or replacements using quality salvaged parts.

Leave a Reply

You must be logged in to post a comment.